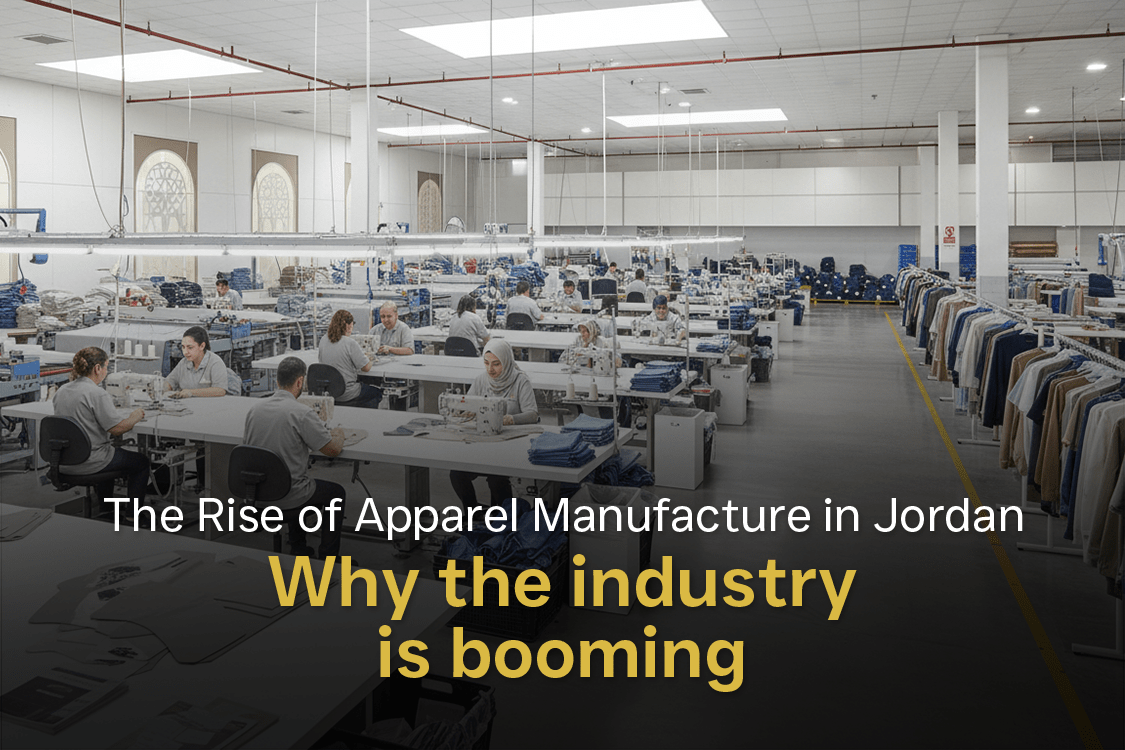

Nestled in the Middle East, Jordan has been steadily rising as one of the most significant sites for a flourishing apparel manufacturing industry. Once known mainly for its tourism industry, Jordan is now home to big clothing businesses as well.

Apparel manufacturing in Jordan is now attracting contributions from big investors. Faster shipping services to Europe, trade deals that bring down tariffs and the development of new local mills with government support create a ripe possibility for flourishing apparel industries. Let us find out why Jordan is one of the smartest choices for apparel brands seeking faster, closer and more systematic sssupply chains.

Why apparel brands and consumers are closing in on Jordan

Over the last decade or so, garment exports from Jordan have grown significantly, reaching $2.26 billion in 2022. The industry is supported not just by local entrepreneurs but foreign investors as well. The country’s stability, skilled workforce and improving infrastructure have led global brands to test its potential as an apparel production site. Here are some of the key reasons as per market research agency in UK why apparel brands and consumers alike are looking to expand their production base in Jordan –

- Short lead times to Europe and the Middle East: As compared to the long shipping routes from Asia, Jordan gives brands faster routes to reach EU and regional markets. This matters for consumers who want quicker turnarounds for their orders and faster restocks.

- Competitive markets: Jordan has trade arrangements that make exported clothing more competitive in big markets. The US-Jordan Free Trade Agreement and the country’s Qualified Industrial Zones have helped apparel produced in Jordan to get easier entry to the US and other markets.

- Near-sourcing benefits: Jordan sits closer to the warehouses, which eliminates the need for long supply chains and high freight costs for European retailers. The geographical location brings down time in transit and the risks related to long routes.

Strong investments and new capacities

Growth, both infrastructural and economic, is consistent in Jordan. In April 2024, King Abdullah II inaugurated the BIA Textile Company, a synthetic-fibre and textile investment that reported at about $149 million. The investment towards spinning and fabric production in the country reduces its dependence on foreign fabrics. It also gives local government factories more control over production quality and timing.

Other new garment factories have also opened in recent years in Jordan. Some of these have direct support from the government. These projects create jobs outside Amman and make the industrial zones for apparel manufacturing in Jordan stronger from within.

The availability of the workforce

The Jordan apparel industry also offers a labour pool that is appealing for investors and entrepreneurs for diverse reasons –

- Skilled sewing and factory-level staff: Jordan’s garment industry has grown enough for experienced sewing experts, line supervisors and quality-control staff to be available. Many firms also invest in on-the-job training to meet the standards of particular brands.

- A mixed workforce: The apparel manufacturing industry employs both local and migrant workers. In some places, investment projects are framed to create jobs for highly unemployed communities. This allows manufacturers to have flexibility in business while also promoting local development.

- Social and compliance programs: International buyers want safer workplaces and better labour standards from the brands they will buy from and trust. Jordan has been home to many programs for improving factory environments and compliance with international labour practices. This is a point all big global brands will consider when picking suppliers.

Policies and incentives

The country’s policy has also actively tried to support exports in apparel manufacturing in Jordan –

- Industrial zones and incentives: Special industrial zones like Qualified Industrial Zones, which were established to encourage exports, give firms simpler customs procedures and duty benefits for meeting origin rules. These measures bring down the cost of exporting finished products.

- Government support for high-value projects: Royal and government attention towards the Jordan apparel industry, including public inaugurations of factories, signals clear political support. This helps to attract both local and foreign investors.

What sets Jordan apart

Jordan’s growing garment industry offers unique benefits for businessmen and investors that go beyond low-cost labour. From locational convenience, investor-friendly policies, to a growing industrial base, everything gives manufacturers an edge in the fast-changing fashion market. These strengths make Jordan a reliable and future-ready apparel sourcing hub.

- Speed and flexibility: Jordan is the perfect place for short-run production and fast replenishment. Brands that sell seasonal stock or trend-inspired ones can choose Jordan to reduce the time between design and store staff.

- Trade access to the U.S. and Europe: FTAs and QIZs in Jordan create the scope for tariff and customs benefits, which make the country competitive as compared to suppliers who have to face higher duties.

- Growing upstream ability: With new investments in textile and synthetic-fibre mills, the country is slowly gaining the ability to produce more fabric locally, besides the good quality of cotton fabric. This is a key step for bringing down lead times and risks of sourcing.

- Regulatory visibility and compliance programs: International initiatives, as well as local efforts to create better workplace standards, make the country more appealing to brands looking for ethical suppliers.

Conclusion

If the current developments continue for the next few years, Jordan could grow as a significant site for high-quality apparel exports as well as local production. Local investments will also reduce the dependence on global apparel sourcing and strengthen factories at home. Continued governmental support and private investments will be crucial, while policymakers and manufacturers must manage geopolitical and shipping risks and encourage worker training and sustainability.

FAQs

- Why is Jordan rising as an apparel manufacturing hub?

Jordan is gaining global attention for its strategic location, trade agreements with the US and Europe. Its stable economy, as well as strong commitment towards ethical forms of production, also makes it an attractive production base for clothing brands. It also offers shorter lead times, better compliance standards and strong government support for textile investors.

- What kinds of apparel are mostly produced in Jordan?

Factories in Jordan produce a wide range of clothes, including denim, sportswear, activewear and more. Many of these are exported to the US and other European markets under free trade benefits.

- How do Jordan’s Qualified Industrial Zones(QIZs) help exporters?

QIZs help to provide duty-free and quota-free access to the US market for products that meet particular origin requirements. They also simplify customs procedures, bring down the costs of exporting the products and make garments made in Jordan competitive in international markets.

- What challenges does Jordan face in the manufacturing of apparel?

The main challenge faced by Jordan in the field of apparel manufacturing includes dependency on raw materials imported from foreign countries and disruptions of transport in particular regions. Another challenge is competition given by larger low-cost producers. Still, it is to be considered that ongoing investments in textile mills in Jordan, as well as the increasing development of logistics, are slowly eliminating these challenges.

- Is Jordan a sustainable choice for fashion brands as a production base?

The short answer to this question is yes. Jordan has already made quite a lot of progress when it comes to ethical and sustainable manufacturing of garments. Programs like the Better Word Jordan and other social initiatives have made Jordan progress in this path. The factories in Jordan are creating the scope for better labour standards, cleaner processes of production and transparent supply chain practices.

Be First to Comment