Metals play a pivotal role in industrial building and manufacturing. They provide the backbone for structures and machinery alike. But what types of metals are most commonly used?

This question leads to a fascinating exploration of metal fabrication. In this comprehensive guide, we will uncover the different types of metals that can be fabricated. From the strength of steel to the conductivity of copper, understanding these materials is crucial.

Each type of metal offers unique properties and benefits. Join us as we explore how these materials shape the world of industrial building.

Metal Fabrication

Let’s first understand what metal fabrication is. It is the process of cutting, shaping, and assembling raw materials into a final product. It can range from large-scale structures like skyscrapers to smaller pieces like car parts.

Metal fabrication requires a combination of specialized skills, tools, and techniques. It is to create the desired end product.

Commonly Used Metals in Fabrication

There are countless types of metals used in metal fabrication. Each metal has its unique properties and characteristics.

Yet, there are a handful that are most commonly used due to their availability and practicality. Let’s take a closer look at these metals and their applications in the world of fabrication.

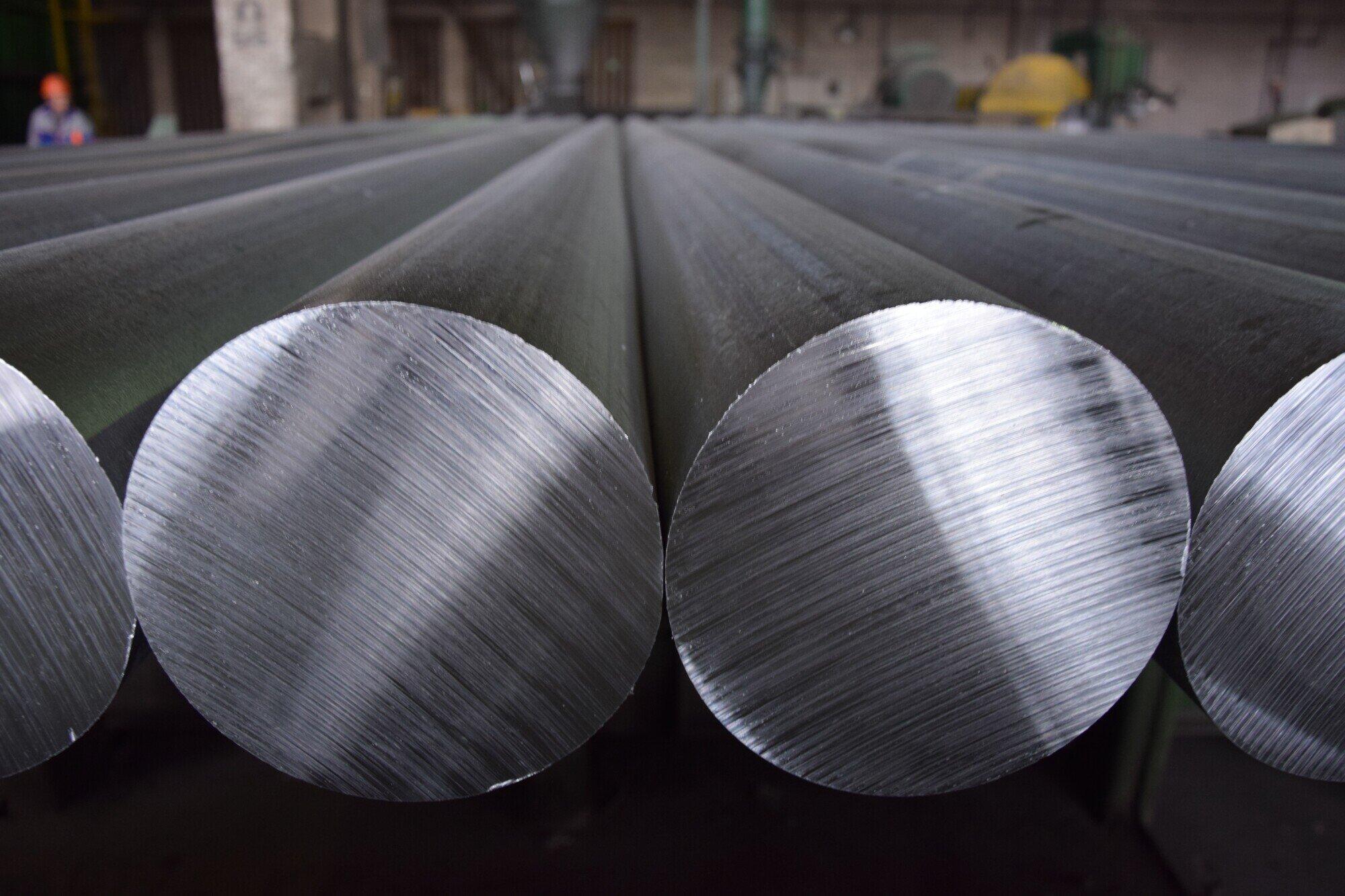

Steel

Steel is a very strong metal made from iron and carbon. It is used a lot because it is tough and lasts a long time. People use steel to build big things like bridges, buildings, and cars.

It can be made into different shapes easily, which makes it very useful. There are many kinds of steel, each with its special qualities. Some kinds of steel can stand up to rust and weather very well.

It is good for things that are outside all the time. Steel can also handle high heat, which is important for engines and machines. It is a key metal in fabrication because it is so versatile and reliable.

Aluminum

Aluminum is another metal that is very popular for making things. It is light and can resist rust. People like to use aluminum for cars and airplanes because it does not weigh much.

This metal is also good for making cans and foil. Aluminum is very good at conducting electricity, so it is used in wires and electronics. Even though it is light, aluminum is strong and can be shaped in many ways.

It makes it very useful for different kinds of jobs. Making aluminum uses a lot of energy, but recycling it saves a lot of that energy. This is why many people try to recycle aluminum cans and other aluminum items.

Copper

Copper is a special kind of metal that people use a lot. It is mostly known for being very good at handling electricity. This is why copper is often used in wires and electronics.

It’s not just good for electricity; copper can also be shaped very easily. It makes it great for making pipes and tubes for water or gas.

Copper is a shiny, reddish-brown metal that stands out because it can fight off rust. It doesn’t react with water easily, which means it lasts a long time even when it’s used outside or where it’s wet.

People have used copper for a very long time, for making things and for coins and art. Even though copper is very useful, it needs to be used carefully.

Too much copper can be bad for the environment. Recycling copper is a good idea because it saves energy and helps the planet.

Stainless Steel

Stainless steel is a kind of metal that doesn’t rust. It is made by mixing steel with chromium. This mix makes it strong and keeps it shiny for a long time.

People use stainless steel in kitchens for pots, pans, and knives because it doesn’t rust and is easy to clean. It’s also used in buildings and cars because it can take a lot of wear and tear without breaking down.

Stainless steel is good for places where there’s a lot of moisture because it won’t get damaged by water. This metal is a bit heavier than aluminum, but it’s still used a lot because it lasts a long time and looks good.

Recycling stainless steel is good for the earth. It saves energy and resources.

Brass

Brass is a metal that people use for many things. It’s made from copper and zinc mixed. Brass is often used because it looks nice and can be shaped easily.

You can find brass in musical instruments like trumpets and things around the house like door handles. Brass is also good for making things that need to fit together tightly, like locks and gears. This metal does not rust easily, which makes it great for outdoor use.

Brass has a gold-like color that many people like for decoration. It’s heavier than aluminum, but still not too heavy.

Recycling brass is a good idea. It saves energy and helps the earth. Brass is an important metal for making many useful items.

Titanium

Titanium is a very strong metal, but it is also very light. It is not heavy like some other metals. It makes it special.

People use titanium in airplanes and sports equipment because it is strong but does not add a lot of weight. It is also used in making medical stuff, like tools for doctors and parts for people’s bodies, like hip replacements.

This is because titanium does not react badly with the human body. It can stay inside a body without causing problems. Titanium does not rust or break down easily, even when it gets wet or is used in salty water.

It is good for things used in the ocean or on ships. Titanium is hard to find and hard to make into things. This is why it costs more than some other metals.

But because it is so useful and lasts a long time, many people think it is worth the cost. Recycling titanium is also good because it saves resources.

Choosing the Right Metal for Your Project

For metal fabrication, choosing the right type of metal is crucial for the success of your project. Each type of metal has its strengths and limitations, so understanding their properties is key. Consider factors such as strength, corrosion resistance, conductivity, and weight when selecting a metal.

Consulting with a professional fabricator can also help you make an informed decision based on your specific project needs. Think about the metal’s workability and how it will be shaped or welded. The cost of the metal and its availability might also impact your choice.

The environmental conditions the metal will be exposed to should influence your selection. Researching and testing various metals can ensure the longevity and success of your project.

Fabrication Techniques for Different Metals

Different types of metals need different fabrication techniques to produce the desired end product. These include:

Welding

Welding is the process of joining two or more pieces of metal together through the use of heat and pressure. This technique is often used for steel and aluminum fabrication, as it creates a strong bond between the metals.

Cutting

Cutting involves separating large sheets of metal into smaller, more manageable pieces using tools such as saws or laser cutters. Different metals may need different cutting techniques depending on their thickness and hardness.

Bending

Bending is the process of manipulating metal into a desired shape using specialized tools, such as a press brake or roll-forming machine. This technique is commonly used for thinner metals like aluminum and copper.

Casting

Casting involves pouring molten metal into a mold to create a specific shape. This technique is commonly used for metals like brass and stainless steel, as well as in the production of intricate parts.

Innovations in Metal Fabrication

As technology continues to advance, so does the world of metal fabrication. New techniques and technologies are constantly being developed. It is to make the process more efficient and cost-effective.

For example, advancements in 3D printing have allowed for faster and more precise fabrication of complex metal parts. Laser-cutting machines are becoming popular due to their precision and speed.

This surge in innovation benefits custom metal fabrication. It enables manufacturers to meet unique client specifications with greater accuracy and efficiency. It further pushes the boundaries of what can be achieved in metalwork.

Sustainability in Metal Fabrication

Sustainability is also becoming a top priority in metal fabrication. Various techniques and processes, such as water jet cutting and powder coating, are being implemented to reduce waste and energy consumption. The use of recycled metals is becoming more prevalent in fabrication projects.

Challenges in Metal Fabrication

While metal fabrication has come a long way with technological advancements, there are still challenges that fabricators face. One major challenge is the high cost of materials and equipment. It makes it difficult for small businesses to compete in the industry.

Fabricators also have to continuously adapt to changing industry standards and regulations. It can be time-consuming and costly.

Learning More About Different Types of Metals

Different types of metals enable diverse projects. Each metal brings unique strengths to fabrication efforts. The welding process stands out for metal unification.

It merges distinct metals into formidable structures. Sustainability drives the choice of types of metals today. Innovations enhance the efficiency of the welding process.

Future advancements promise even finer metal fabrications. The versatility of metals enriches the fabrication landscape. The right metal propels projects toward success.

Did you find this article helpful? If so, check out the rest of our site for more informative content.

Be First to Comment