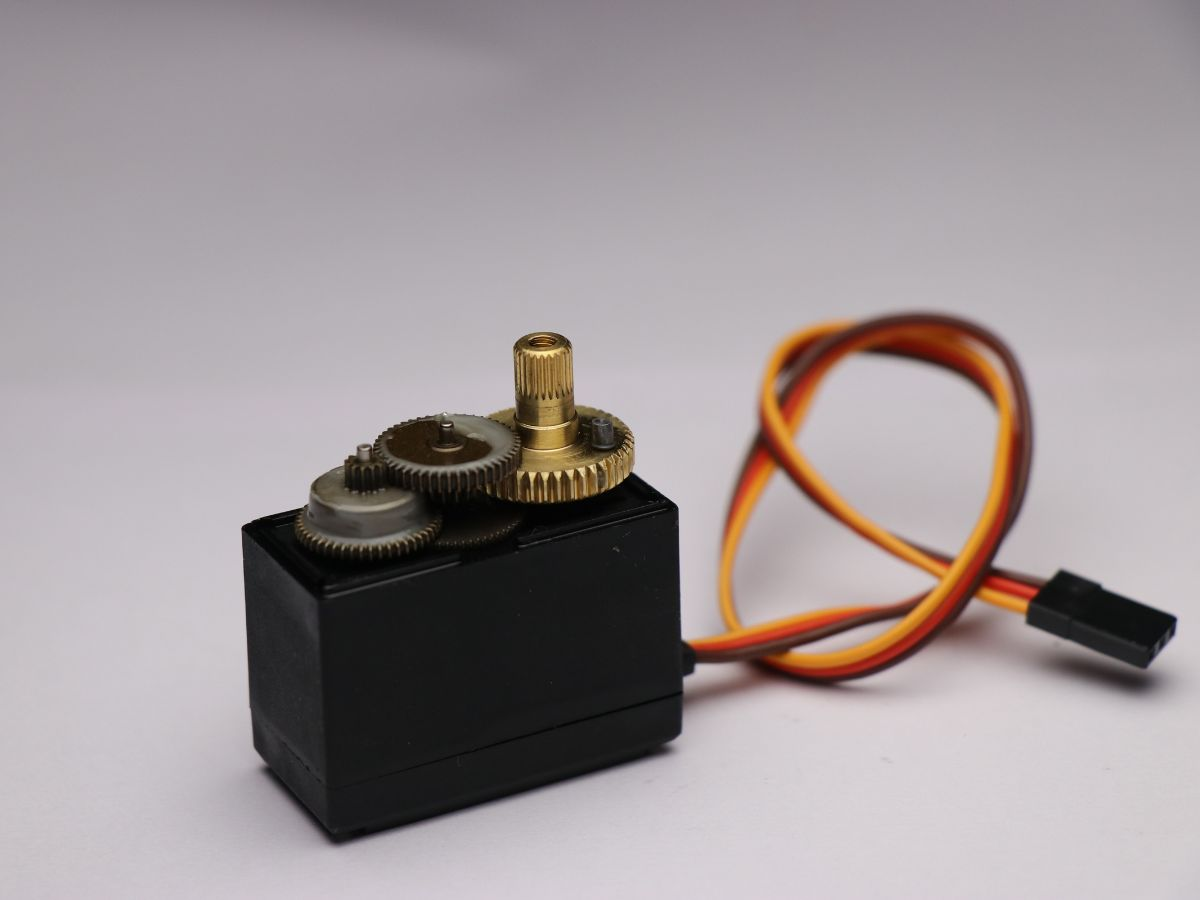

I remember standing in a bustling Chinese workshop, watching a tiny servo motor power through tasks like it was nothing.

It was mesmerizing.

That day sparked my mission to track down the best servo motor makers in China. Over the years, I’ve talked to countless engineers, tested these motors in the field, and seen firsthand which companies truly deliver. Some are well-known giants, while others, like trusted manufacturers like Radin, have built a reputation for offering dependable, OEM-friendly solutions that don’t cut corners.

This isn’t just guesswork. In this article, I’ll introduce you to the top 7 servo motor manufacturers in China and explain what sets each of them apart. You’ll leave knowing exactly who’s worth your investment.

Trust me, the difference between a good motor and a great one can transform your production line.

Let’s get started!

1. Radin

When I first encountered Radin’s products, I was struck by how confidently they handled complex power distribution tasks. Radin doesn’t just make reliable electrical components; they engineer solutions that truly meet industrial challenges head-on. That commitment to performance and innovation is what sets them apart in the servo motor and automation space.

- Headquarters: No. 55 Punan 5th Rd, Economic Development Zone, Yueqing, Zhejiang, China

Key Industries Served

- Generator Sets (Gensets)

- Power Distribution

- Industrial Automation

- Infrastructure Projects

- Building Services

- Data Centers & Telecom

- Manufacturing Plants

Core Products

- Circuit Breaker: Includes Moulded Case Circuit Breaker and Air Circuit Breaker models. These robust breakers ensure reliable circuit protection and performance under heavy electrical loads.

- Automatic Transfer Switch: Features Motorized Transfer Switch (PC), Solenoid Transfer Switch (PC), and Automatic Transfer Switch (CB). These switches guarantee fast and seamless power transfer in emergency backup systems.

- Surge Protective Device: Available in Type 1, Type 2, Type 3, and DC SPD models. Each is engineered to guard against voltage spikes and protect sensitive equipment.

- Sensor: Ranges from inductive, capacitive, and Hall effect sensors to optical fibre and color sensors. They enable precise position and status monitoring in automated systems.

- Relay: Electromagnetic relays, solid state relays, and high voltage DC relays are part of their offering. These relays ensure stable operation of electrical circuits and systems.

- Switch: Limit switches, microswitches, and indicator lights are included. Each is designed for reliable operation in harsh industrial environments.

- Motor Starter: Products like star delta starters and motor circuit protectors. These starters provide safe motor control for a range of industrial applications.

- Magnetic Contactor: Includes AC and DC contactors to suit different power and control needs. They offer high durability and easy integration.

- Servo Drive & Servo Motor: Their advanced servo solutions provide precise motion control for a wide range of factory automation tasks.

- Variable Frequency Drive & Soft Starter: Engineered for smooth motor operation and energy efficiency. These drives help reduce energy costs and prolong equipment life.

Strengths & Certifications

- Proven Reliability and Engineering: With decades of experience, Radin’s engineering teams have refined every product for real-world performance. This ensures that their equipment holds up under tough operating conditions.

- Global Standards Compliance: Their products meet international certifications like CE and TÜV, so you know you’re getting components that can be trusted in demanding applications.

- Innovative Approach: Radin continually pushes boundaries, offering technically advanced products that solve complex engineering challenges. From high-speed switching to energy-saving sensors, they’re always improving.

- Robust Testing and Quality: Each product goes through comprehensive testing, including mechanical lifespan testing and environmental verification, to guarantee maximum reliability.

- Customer-Focused Customization: Radin’s team works closely with partners to tweak parameters, meet unique project needs, and deliver customized solutions. This flexibility makes them a great choice for engineering teams and contractors worldwide.

- Extensive Product Range: From simple relays to sophisticated servo drives, Radin’s diverse offerings let you build complete solutions with components that work seamlessly together.

Bottom Line

Radin stands out for its incredible product range and proven reliability across so many industrial applications. Their innovative approach and customer-centric mindset makes sure businesses have a dependable partner for every project. There’s really nothing to hold against Radin, they’ve set the bar high in every way. From sensors to motor control solutions, they truly cover the entire automation landscape.

2. Inovance

When I first explored Inovance’s product line, I was impressed by their comprehensive approach to industrial automation. Their commitment to innovation and quality is evident in their diverse range of products and solutions. Their rapid growth and expansion into international markets underscore their position as a leading force in automation technology.

- Headquarters: Inovance Headquarters Tower, High-tech Industrial Park, Guanlan Street, Longhua New District, Shenzhen, Guangdong Province, China

Key Industries Served

- Industrial Automation

- Elevator and Escalator Systems

- Electric Vehicles

- Rail Transit

- Textile Machinery

- Printing and Packaging

- HVAC Systems

- Oil and Gas

- Renewable Energy

Core Products

- AC Drives: Inovance offers a range of AC drives designed for various applications, providing energy-efficient and precise motor control solutions.

- Servo Drives and Motors: Their servo systems deliver high-performance motion control, suitable for applications requiring precision and reliability.

- Programmable Logic Controllers (PLCs): Inovance’s PLCs are versatile and scalable, catering to complex automation processes across industries.

- Human-Machine Interfaces (HMIs): Their HMIs provide intuitive interfaces for operators, enhancing control and monitoring capabilities.

- Motion Controllers: These controllers offer advanced motion control features, enabling synchronized multi-axis operations.

- CNC Solutions: Inovance provides comprehensive CNC systems for machine tools, enhancing high-precision machining processes.

- Industrial Robots: Their robotic solutions are designed for tasks such as assembly, welding, and material handling, improving productivity and consistency.

- Elevator Control Systems: Inovance’s integrated elevator solutions enhance safety, efficiency, and ride comfort in vertical transportation.

- Electric Vehicle Inverters: They offer inverters for electric vehicles, contributing to efficient power conversion and vehicle performance.

- Rail Transit Systems: Their products support traction and control systems in rail applications, enhancing reliable and safe operations.

Strengths & Certifications

- Global R&D Network: Inovance invests heavily in research and development, with teams across China, Europe, and India collaborating to innovate and improve product offerings.

- International Standards Compliance: Their products meet major global certifications, including CE, UL, and EAC, providing safety and reliability in various markets.

- Robust Manufacturing Capabilities: With multiple production bases and advanced manufacturing techniques, Inovance guarantees high-quality and scalable production.

- Comprehensive Testing Facilities: They maintain state-of-the-art testing labs for EMC, environmental, and functional testing, adhering to ISO/IEC 17025 and ISO 9001 standards.

- Customer-Centric Approach: Inovance emphasizes tailored solutions, working closely with clients to meet specific application requirements and challenges.

- Sustainable Growth Strategy: Their “global-local” strategy focuses on combining global innovation with local operations to better serve diverse markets.

Bottom Line

Inovance’s dedication to smart automation and global standards compliance makes them a powerhouse in the industry. Their expansive R&D and robust product lines cater to diverse business needs with precision. The only downside is that their solutions may sometimes lean towards premium pricing, which could stretch smaller budgets.

3. Estun

When I first came across Estun, I was fascinated by their deep roots in motion control and how seamlessly they merged it with robotics. What I love about Estun is their commitment to not just make components, but to offer complete solutions that elevate entire production lines. Their global reach and innovation-driven mindset make them a strong partner for businesses that demand the best.

- Headquarters: No. 6, Weidi Road, Jiangning District, Nanjing, Jiangsu Province, China

Key Industries Served

- Metal Processing Machinery

- Automotive Manufacturing

- Electronics and 3C Assembly

- Photovoltaic (Solar) Equipment

- Packaging Machinery

- Welding Automation

- Engineering Machinery

- Aerospace and Aviation

Core Products

- AC Servo Systems: Estun’s flagship product category, offering servo drives and motors that guarante smooth, precise, and fast-response motion control. These are used widely in CNC machinery and industrial robots.

- Frequency Inverters: These inverters help businesses optimize motor speed and energy usage, which not only saves power but also extends equipment life.

- Motion Controllers: Estun’s motion controllers coordinate multi-axis movement with pinpoint accuracy, making complex automation simple and reliable.

- Industrial Robots: Their range of robots, including six-axis models, are designed for everything from welding to assembly, helping factories boost productivity.

- PLC & HMI Solutions: These control interfaces connect equipment and operators in smarter, more efficient ways, paving the path for modern digital factories.

- Complete Automation Solutions: Estun offers holistic solutions that combine motion control, drives, and robotics into one cohesive system, eliminating compatibility headaches and improving performance.

Strengths & Certifications

- Pioneer in Servo Systems: As one of the first Chinese companies to independently develop AC servo systems in the 1990s, Estun has a track record of excellence in motion control technology.

- Global Certification Compliance: Estun products proudly carry CE marks and meet strict international standards, enhancing safety and reliability worldwide.

- Strong Focus on R&D: With a dedicated research team and decades of experience, Estun continually brings new innovations to the market, staying ahead of evolving manufacturing needs.

- International Expansion: Estun has built a global presence with offices and partners across Europe, Asia, and beyond, providing local support to international customers.

- Integrated, End-to-End Solutions: Estun’s ability to deliver fully integrated automation solutions – from servos to robots – gives them an edge in helping businesses streamline and future-proof their operations.

Bottom Line

Estun’s decades-long expertise in motion control and robotics helps businesses achieve consistent, precise performance in their production lines. Their strong R&D focus and international certifications mean you can trust their products to perform anywhere. However, some users have noted that their servo systems might not be as price-competitive in certain markets.

4. Leadshine

The first time I learned about Leadshine, I was surprised by how a company could offer such a strong balance between quality and affordability. They’ve taken the guesswork out of motion control with products that just work, right out of the box. Leadshine’s dedication to innovation and practical engineering makes them a trusted partner for countless businesses worldwide.

- Headquarters: No. 8, Baolong 2nd Road, Longgang District, Shenzhen, Guangdong Province, China

Key Industries Served

- CNC Machinery

- Electronics and Semiconductor Equipment

- Logistics and Warehouse Automation

- Printing and Packaging

- Medical Equipment

- Automated Devices and Robotics

Core Products

- AC Servo Motors and Drives: Leadshine’s servo motors and drives deliver precise motion control and reliable performance for CNC machines, industrial automation, and more.

- Integrated Servo Motors: These compact units combine a motor and driver in one, saving space and simplifying installation for streamlined machine builds.

- Closed-Loop Stepper Systems: A standout product, these systems offer the benefits of stepper motors with the feedback of servos, striking a balance between cost and performance.

- Stepper Motors and Drives: Known for reliability and cost-effectiveness, these are ideal for simpler motion control tasks and small-scale machinery.

- Motion Controllers: Their controllers help orchestrate multi-axis movement and optimize machine performance with robust control features.

- CNC Motion Solutions: Leadshine offers a range of integrated motion systems designed specifically for CNC machinery, making precision easy for manufacturers.

Strengths & Certifications

- High Quality at Competitive Prices: Leadshine has built a reputation for offering industrial-grade products that rival more expensive brands, making them a cost-effective choice for businesses.

- ISO9001 Certified: With strict quality controls in place, they make sure every product leaving their facility meets the highest standards of reliability and durability.

- Global Reach: Leadshine exports to over 60 countries, so you can find their support and products no matter where your business is based.

- Comprehensive Testing: Each product undergoes thorough functional testing, including 24-hour powered trials, making sure it’s up to the task in any environment.

- Engineering Expertise: With a large R&D team and years of motion control experience, Leadshine delivers solutions that blend practical functionality with innovation.

- Flexible Integration: Their motion products work together seamlessly, allowing for easy scaling and customization as your automation needs evolve.

Bottom Line

Leadshine’s balance of quality and affordability makes them a great option for businesses scaling up their automation needs. Their products are well-engineered and thoroughly tested, providing reliability and peace of mind. But they may not be the best fit for highly specialized or ultra-high-end applications.

5. Kinco Automation

The first time I explored Kinco’s offerings, I was impressed by their focus on making smart automation solutions accessible to everyone. Their products blend performance and value, showing they really understand what manufacturers need. I appreciate how Kinco doesn’t just make parts; they create integrated systems that help businesses boost productivity and streamline operations.

- Headquarters: 3/F, Building 4, Baolong Industrial City, Longgang District, Shenzhen, Guangdong Province, China

Key Industries Served

- Factory Automation

- Warehouse and Logistics Systems

- Medical Equipment

- Service Robotics and AGVs

- 3C Manufacturing

- Textile Machinery

- Packaging Machinery

- Precision Machine Tools

Core Products

- AC Servo Motors and Drives: Kinco’s servo systems provide precision motion control for industrial equipment, enabling smooth, reliable performance.

- DC Servo Motors and Drives: Compact and cost-effective, these DC solutions deliver steady performance for smaller automation tasks.

- Stepper Motors and Drives: Ideal for simpler motion control applications, Kinco’s stepper systems are known for their dependability.

- Human-Machine Interfaces (HMIs): These user-friendly touchscreens help operators easily control and monitor processes in real time.

- Programmable Logic Controllers (PLCs): Kinco’s PLCs are designed for flexibility and can handle a range of complex automation tasks.

- Motion Controllers: These controllers coordinate multi-axis motion in machines, making sure every move is precise and efficient.

- Variable Frequency Drives (VFDs): Designed for smooth motor control and energy savings, these drives boost system efficiency across applications.

- Integrated Servo Wheel Drives: These innovative units combine a motor, gearbox, and driver for AGVs and robots, reducing complexity in mobile solutions.

Strengths & Certifications

- One-Stop Automation Solutions: Kinco offers complete automation packages, so customers can source everything from HMIs to servo motors from a single supplier.

- Strong R&D Focus: With dedicated research teams and multiple innovation centers, Kinco stays ahead of trends in industrial automation and smart factories.

- ISO9001 Certified: Their products meet strict international quality standards, establishing safety, durability, and reliability across projects.

- Tailored Solutions for Robotics: Kinco’s integrated wheel drives and motion control products cater to the growing service robot and AGV market.

- Commitment to the IIoT: Kinco integrates cloud connectivity and smart monitoring into their solutions, helping customers future-proof their operations.

- Global Support and Expansion: Kinco’s strong network of partners and offices worldwide means you’ll always find help and support when you need it.

Bottom Line

Kinco Automation is known for its holistic approach to industrial automation, offering everything from HMIs to servo wheels for AGVs. Their focus on smart factory solutions is perfect for forward-thinking businesses. One area for improvement is their international market presence, which isn’t as robust as some of the bigger names.

6. GSK CNC

The first time I came across GSK, I was impressed by how they’ve shaped China’s CNC industry. They’ve turned what used to be a costly foreign technology into something more accessible for local and global businesses alike. What sets GSK apart is how they integrate everything from controls to servo motors in one smart package.

- Headquarters: No. 1, GSK Industrial Park, Xintang Town, Zengcheng District, Guangzhou, Guangdong Province, China

Key Industries Served

- CNC Machine Tools

- Metal Cutting and Forming

- Automation Retrofits

- Aerospace Component Machining

- Education and Training in Vocational Schools

- General Manufacturing Automation

Core Products

- CNC Controllers: GSK’s flagship products, these controllers are built for everything from lathes and milling machines to complex multi-axis machining centers.

- AC Servo Motors and Drives: Designed to deliver reliable, precise motion in CNC applications, these servo solutions keep machine tools performing at their best.

- Spindle Servo Systems: GSK’s high-speed spindle drives and motors are engineered to meet the demands of precision machining and high-speed cutting.

- Industrial Robots: Their small 6-axis robots are designed for welding, assembly, and light handling tasks, broadening their automation capabilities.

- Retrofit Kits: GSK offers upgrade kits for older machines, letting customers modernize without replacing their entire setup.

- Complete CNC Systems: Beyond separate components, GSK sells integrated packages that bring CNC motion, control, and monitoring together seamlessly.

Strengths & Certifications

- Deep Integration Expertise: GSK is known for integrating CNC controls and servo technology into a complete, reliable system that’s easy to use and maintain.

- National High-Tech Enterprise: They’ve been recognized in China for pushing innovation and helping to localize advanced CNC technology.

- Widespread Local Support: With training centers and service teams across China, GSK guarantees their customers get fast, effective help when they need it.

- Robust Quality and Testing: Their products are built to strict Chinese and international standards, with CE certifications for export-ready reliability.

- Affordable CNC Automation: GSK helps businesses tap into advanced automation without breaking the bank, making precision machining more accessible.

- Ongoing Product Development: They’re continuously improving their servo and CNC technology, staying competitive in a market that’s always evolving.

Bottom Line

GSK’s deep integration of CNC controls and servo motors offers a seamless, reliable solution for precision machining. Their focus on affordability and local support gives them a major edge in cost-sensitive industries. However, some users say their technology isn’t quite as cutting-edge as top-tier Japanese or European brands.

7. INVT

When I first explored INVT’s product range, I was impressed by how they combined strong drive technology with advanced servo systems. They have a knack for making energy-efficient, reliable solutions that work for all kinds of industries. What sets them apart is how they leverage their years of experience in power electronics to refine every detail in their servo systems.

- Headquarters: No. 4, Gaoke Middle Road, Nanshan District, Shenzhen, Guangdong Province, China

Key Industries Served

- Lifting and Cranes

- Mining and Metallurgy

- Textile Machinery

- Machine Tools

- Plastics Manufacturing

- Oil and Gas

- Municipal Engineering

- Power Generation

- Rail Transit

- Building Automation

- Renewable Energy

Core Products

- AC Servo Systems: INVT’s servo motors and drives are engineered for precision and energy efficiency, making them a reliable choice for demanding automation tasks.

- Variable Frequency Drives (VFDs): Known for smooth motor control and energy savings, these drives are a core part of INVT’s offering.

- Programmable Logic Controllers (PLCs): These PLCs are versatile and support a wide range of industrial control applications.

- Human-Machine Interfaces (HMIs): User-friendly screens that bring clear and intuitive control to the shop floor.

- Motion Controllers: These advanced controllers manage multi-axis motion, perfect for applications where accuracy is critical.

- Electric Vehicle Inverters: Part of INVT’s push into new energy, these inverters deliver efficient power conversion for EVs.

- Rail Transit Traction Systems: Specialized traction converters and drives for the rail industry, combining power and safety.

- Building Automation Solutions: Drives and control products for elevators, HVAC systems, and energy-saving building systems.

Strengths & Certifications

- Power Electronics Expertise: INVT’s roots in inverter technology mean their servo systems come with unmatched energy efficiency and performance.

- ISO9001 Certified: All their processes are held to global quality standards, and many products carry CE and UL certifications for global market access.

- Continuous Innovation: They invest heavily in R&D, holding multiple patents and developing new solutions to meet evolving industry needs.

- Broad Product Range: From small servo motors to massive industrial drives, INVT has a solution for nearly every application.

- Global Presence: INVT’s network of offices and partners worldwide makes sure that customers everywhere get top-notch service and support.

- Sustainability Focus: Their technologies help customers cut energy use and improve environmental performance, aligning with modern sustainability goals.

Bottom Line

INVT’s broad expertise in drives and power electronics shines through in their high-efficiency servo systems. Their commitment to sustainability and global standards is a huge plus for businesses focused on long-term growth. The only drawback is that their product documentation and support might not be as comprehensive in some export markets.

Conclusion

From my first awe-struck look at a tiny servo motor, we’ve come full circle.

We explored China’s leading 7 brands. Each brings precision and power to modern industries.

Now it’s your turn to make things happen. Find the partner who speaks your language and meets your goals.

Where do you see your business going next?

Be First to Comment