Air-operated valves are widely used in certain industries where different air pressure needs

are required. Petrochemical, food, and beverage industries are among those which utilize

these kinds of electronic air flow control valves. This is due to the high efficiency and long

time run life of these devices. One major application of these electronic flow valves is that

they can be used to flow high-viscosity liquids at very high pressure.

Electronic Flow Control Valve:

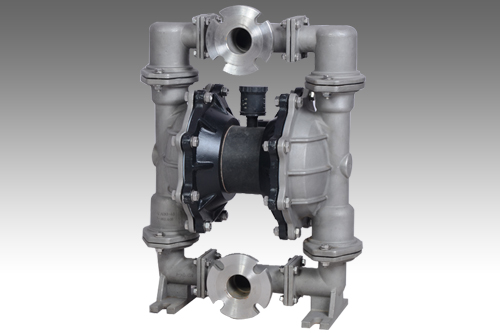

This particular device is a kind of valve that is used to compress air and fluid at high

pressure. There are multiple chambers in the valve that are moved simultaneously with a

network of linked shafts inside the valves. This kind of motion inside the valve remains

continued with pressurized air or fluid. This is why the device is made from the best quality

materials so that it can easily bear the high pressure and strain of the fluids or gases.

Air Compression:

When air is discharged from the compressors, it is usually dirty, wet, and unregulated. This

kind of air may affect the walls of electronic flow control valves. This is why when it comes to

air, you must make sure to keep it at the best quality with maximum pressure throw that

reduces the corrosion on the inside surface of electronic pressure regulator valves.

However, certain industries install special filter regulators that provide assistance in pressure

regulation so that the continuity is not distorted. The advantage is that this external device to

the electronic air flow control valve provides pure air without any contaminants.

Diaphragms:

Electronic valves have a built-in elastomeric diaphragm that helps to pump air or

high-viscosity fluids without any hurdle. The installed diaphragms are so flexible that can

bear extreme pressures of air. On the other hand, the diaphragm allows the air or fluid to

enter through a common inlet and discharge through a single outlet.

Pulsation:

It must be kept in mind that when air or liquid flows out of the electronic flow valve, there is

some pulsation seen on the outcome side. This can disturb the motion of air or fluid inside

the electronic air flow control valve. But connecting the valves with external pulsation

dampeners can reduce the rate of pulsation.

The pulsation dampeners can easily absorb all the pulsation energy developed at the outlet

of the valve. The device has a membrane with a cushion of compressible air. This air

cushion helps to fade the pulse created and dampen it to reduce any flow error. In any

industry or firm, electronic air flow control valves allow reliable pumping at cheaper costs.

Types of Electronic Air Flow Control Valves:

Following are the types of proportional flow control valves:

● 2-Way: Normally opened or closed

● 3-Way: The valve has a particular function by which it can be used to divert the gas

or fluid flow from one direction to another direction.

● 4-Way: These valves are used where extremely high pressures are required to

maintain

Be First to Comment