Hydraulic systems are an integral part of heavy machinery and equipment. Understanding how the main components of a hydraulic system work together can help in hydraulic repair. Knowing when repairs or maintenance may be needed can prevent equipment downtime and allow optimal performance. Here are details about the main components of a hydraulic system.

Hydraulic Fluid

Hydraulic fluid is key to any hydraulic system. That specially formulated fluid transmits power and lubricates components in the hydraulic circuit. Hydraulic fluid needs to have specific viscosity, lubricating properties, and resistance to compressibility. Mineral-based and synthetic fluids like phosphate esters or polyalphaolefins are common hydraulic fluids. Checking fluid levels and replacing hydraulic fluid per the manufacturer’s recommendations helps prevent component damage.

Hydraulic Pump

The hydraulic pump moves the fluid through the system, generating flow and pressure. It pulls low-pressure fluid from the reservoir and discharges high-pressure fluid into hydraulic lines and actuators. Common types of hydraulic pumps include gear pumps, vane pumps, and piston pumps. The pump can provide proper flow rate and pressure for the hydraulic system. Worn or damaged pumps can lead to loss of pressure or overheating.

Control Valves

Control valves manage the hydraulic fluid’s direction, pressure, and flow rate as it travels through the system. Valves open and close to regulate and direct fluid as needed for various machine functions. Relief valves prevent excessive pressure buildup, while flow control valves regulate fluid flow rate. Directional control valves route fluid to different actuators like hydraulic cylinders. Malfunctioning valves can disrupt machine operation.

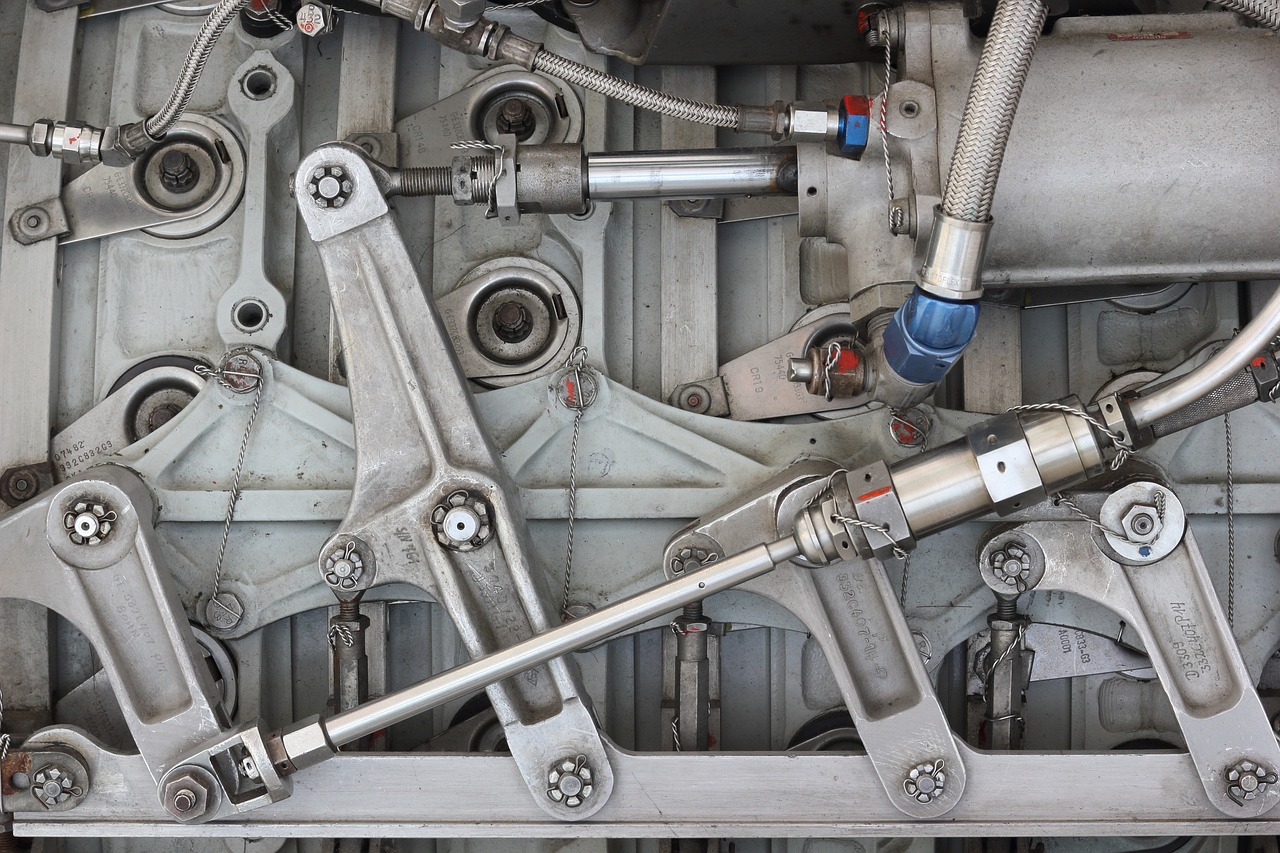

Actuators

Actuators convert hydraulic power into mechanical motion to operate machine components. Standard hydraulic actuators include cylinders, motors, and hydraulic turbines. Cylinders use pressurized fluid to generate linear motion to lift, lower, or move implements. Hydraulic motors harness fluid pressure and flow to produce rotary motion to drive wheels or turn shafts. Detecting leaks, stuck cylinders, or abnormal noise from actuators indicates a need for hydraulic repair.

Hydraulic Lines and Hoses

Hydraulic lines and hoses allow fluid flow through the hydraulic circuit. Hoses have an inner rubber layer covered by outer reinforced fibers. Hydraulic lines are rigid hollow tubes made of steel or aluminum. Hydraulic fluid flows through the hoses and lines between the pump, valves, and actuators. Cracked, worn, or damaged hoses and lines leak fluid, disrupt pressure, and introduce contaminants.

Hydraulic Reservoir

The reservoir stores the hydraulic fluid supply. It also helps remove air bubbles and dissipate heat from the hydraulic fluid. Reservoirs must be large enough to hold the system’s entire hydraulic fluid volume. Keeping the reservoir filled to the proper level helps in proper operation. Low fluid levels allow air to enter the system, leading to cavitation or oxidation.

Heat Exchanger

A heat exchanger cools the hydraulic fluid to help maintain optimal viscosity and prevent overheating. Heat transfers to the cooler ambient environment as the hydraulic fluid flows across the heat exchanger. Maintaining proper hydraulic fluid temperatures improves efficiency and prevents premature component wear. A malfunctioning heat exchanger reduces a hydraulic system’s service life.

Filters

Hydraulic fluid filters remove contaminants that can damage components. Filters trap debris and particles before they enter the pump, valves, and other elements. Various hydraulic filters include suction, return, pressure, and breather filters. Clogged filters cause flow restriction and hinder hydraulic system performance.

Hydraulic Accumulators

Hydraulic accumulators store pressurized hydraulic fluid to provide extra power when needed. That gives a hydraulic system a power boost for peak demand operations. Bladder, piston, and diaphragm accumulators use compressed gas or springs to pressure the hydraulic fluid. Failure of an accumulator can disrupt the hydraulic system.

Find a Reliable Hydraulic Repair Service

Hydraulic systems have several components working together to transmit and control power. Learning the purpose and function of each hydraulic component provides a better understanding of potential maintenance and repair needs. Look for qualified local technicians specializing in “hydraulic repair” to service your hydraulic system. Proper maintenance helps avoid costly downtime and allows optimal performance.

Be First to Comment